In the oil and gas industry, the integrity and performance of pipeline systems are paramount. Carbon steel pipe fittings have become a popular choice due to their numerous advantages. This article delves into the key benefits of using carbon steel pipe fittings in oil and gas applications, highlighting their strength, cost-effectiveness, and versatility.

High Strength and Durability

One of the most significant advantages of carbon steel pipe fittings is their high strength and durability. The oil and gas industry often operates under extreme conditions, including high pressures and temperatures. Carbon steel is known for its impressive tensile strength, which allows it to withstand these demanding environments without deformation or failure.

Moreover, carbon steel fittings are resistant to wear and corrosion when properly treated. This durability ensures that the fittings can handle the aggressive substances commonly found in oil and gas operations, including crude oil, natural gas, and various chemicals. As a result, companies can rely on carbon steel pipe fittings to maintain the safety and efficiency of their systems over time.

This strength and durability are particularly important in applications such as offshore platforms and high-pressure pipelines, where equipment failure could lead to catastrophic results. The ability of carbon steel fittings to perform reliably in these conditions helps minimize downtime and maintenance costs, contributing to overall operational efficiency.

Cost-Effectiveness

In an industry where margins can be tight, cost-effectiveness is crucial. Carbon steel pipe fittings are generally less expensive than alternatives such as stainless steel. This cost advantage makes them an attractive option for large-scale projects in the oil and gas sector, where budgets must be carefully managed.

Additionally, the manufacturing processes for carbon steel are well-established and efficient, further reducing costs. The availability of raw materials also plays a role in keeping prices competitive. By opting for carbon steel fittings, companies can allocate their resources more effectively, allowing for investment in other critical areas of their operations.

It is also worth noting that while the initial costs may be lower, the long-term savings associated with durability and maintenance must be considered. The extended lifespan of carbon steel pipe fittings means that companies will not have to replace them as frequently, leading to lower total ownership costs.

Weldability and Ease of Installation

Another notable benefit of carbon steel pipe fittings is their weldability. The ability to weld fittings seamlessly into existing piping systems is vital for ensuring a leak-proof connection. Carbon steel can be easily welded using various techniques, making it a versatile choice for custom installations.

This ease of installation reduces labor costs and project timelines, allowing for quicker project completion. In the fast-paced oil and gas industry, where time is often of the essence, having fittings that can be installed efficiently can significantly impact overall productivity.

Furthermore, the flexibility in design and manufacturing means that carbon steel pipe fittings can be tailored to meet specific project requirements. Whether a project requires standard sizes or custom shapes, the adaptability of carbon steel allows for the creation of fittings that fit perfectly into any system.

Versatility Across Applications

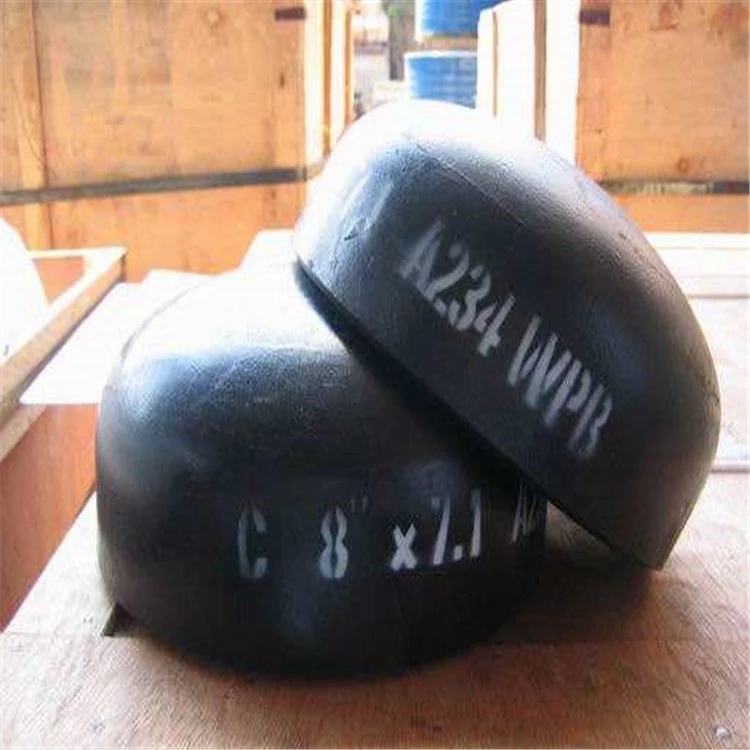

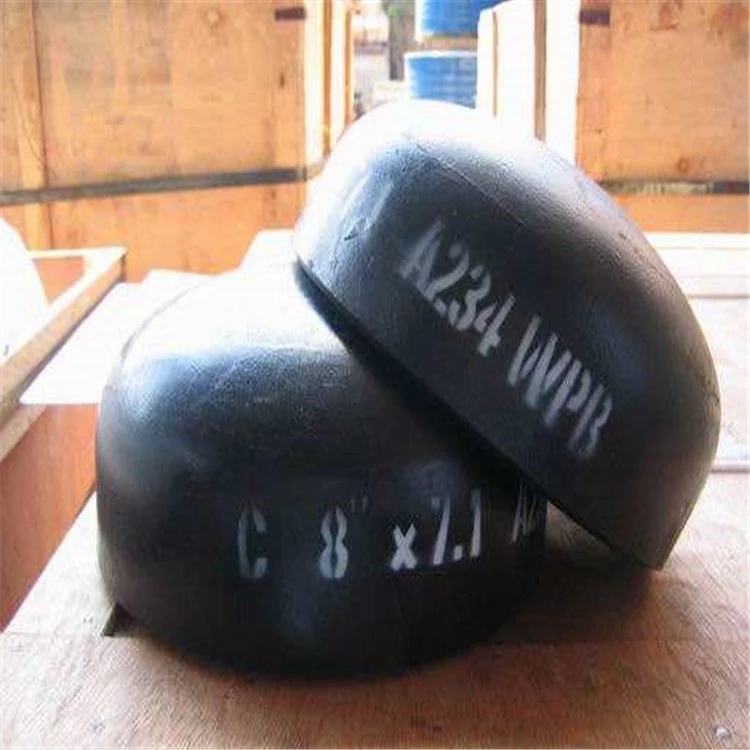

The versatility of carbon steel pipe fittings extends across various applications within the oil and gas sector. These fittings are used in pipelines, refineries, processing plants, and offshore platforms, making them essential components in the industry.

For instance, in oil and gas applications, carbon steel fittings are commonly employed for low-pressure liquid transportation, such as water, gas, and oil. Their robust nature allows them to perform effectively in these roles, ensuring the safe and efficient transfer of materials.

Additionally, carbon steel is compatible with a wide range of coatings and treatments that enhance its corrosion resistance. This compatibility makes it suitable for various environments, including those exposed to harsh weather conditions or corrosive substances.

The ability to adapt carbon steel fittings for specific uses ensures that they meet the diverse needs of the oil and gas industry. Whether for construction pipelines or offshore platforms, the reliability of carbon steel pipe fittings remains unmatched.

Conclusion

In summary, the advantages of using carbon steel pipe fittings in oil and gas applications are clear. Their high strength and durability make them suitable for demanding environments, while their cost-effectiveness and ease of installation contribute to overall project efficiency. The versatility of these fittings across various applications further solidifies their importance in the industry.

As the oil and gas sector continues to evolve, staying abreast of the latest trends and materials is essential. By choosing carbon steel pipe fittings, companies can ensure that their infrastructure remains robust and reliable. For more information on the available products, please visit this page. If you have specific inquiries or need assistance, feel free to contact us for more details.

By investing in high-quality carbon steel fittings, businesses can improve operational efficiency, reduce costs, and enhance safety—essential factors for success in the competitive oil and gas landscape.