The Stainless Steel Elbow is an essential component in various piping systems, especially in industries such as petroleum, chemical processing, power generation, and shipbuilding. Our DN200 Seamless Elbow A234 WPB offers unmatched quality and versatility, adhering to international standards to ensure reliability and performance.

Size and Thickness Options

Our stainless steel elbow is available in a comprehensive range of sizes, accommodating pipes from 1/2" to 24" made from seamless pipes. For larger diameters, we offer welded pipes up to 72". Thicknesses are tailored to meet diverse requirements, including SCH20, SCH40, STD, SCH60, SCHXS, SCH80, SCH160, and SCHXXS.

Angles and Radii

We provide elbows in various angles, primarily 45 degrees and 90 degrees, to suit your piping needs. Customers can choose between long radius elbows with a radius of 1.5d and short radius elbows with a radius of d. This flexibility allows for optimal flow and minimizes pressure loss in your systems.

Compliance with Standards

Our products comply with various international standards, ensuring they meet the highest quality benchmarks. These include ASTMA234, ASTM A420, ANSI B16.9/B16.28/B16.25, and several others, such as JIS B2311-1997, DIN 2605-1, and GB 12459-99. This adherence to standards reinforces our commitment to quality and reliability.

Material Composition

We offer stainless steel elbows made from various high-quality materials, including:

Stainless Steel: Complying with ASTM A403 WP304, 304L, 316, 316L, 321, and others.

Carbon Steel: Options like ASTM A234 WPB, A420 WPL6, 20#, Q235, among others.

Alloy Steel: Featuring ASTM A234 WP12, WP11, WP22, ensuring durability and strength.

This diverse material selection allows us to meet various operational demands and environmental conditions.

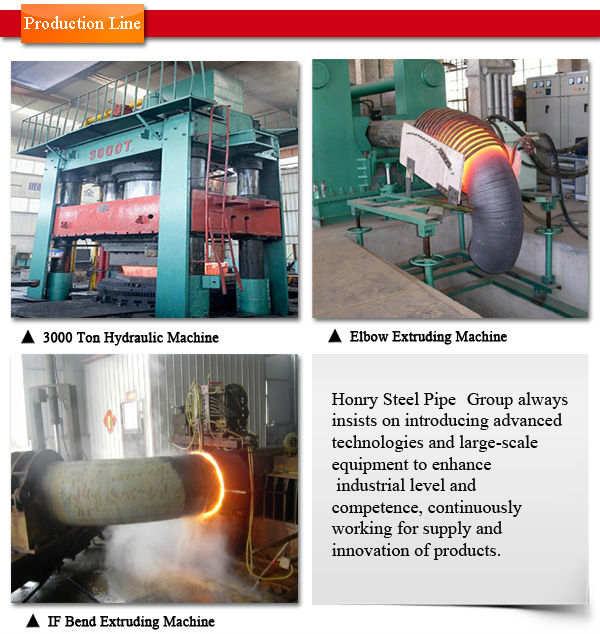

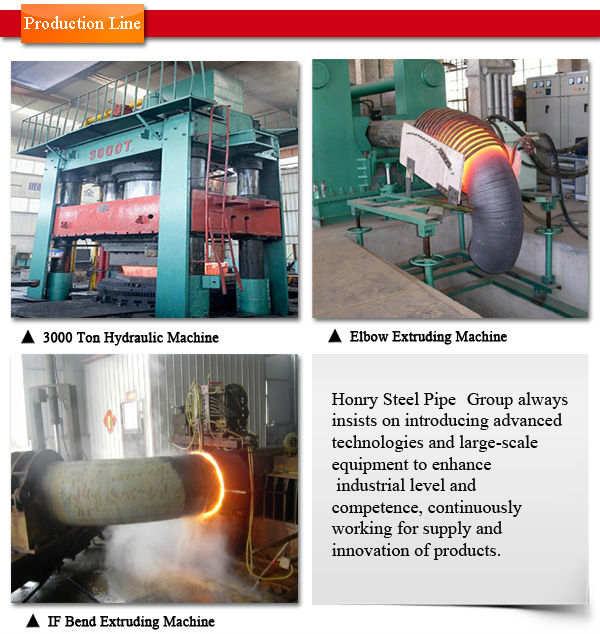

Technology and Connection Types

Our stainless steel elbows are crafted using advanced butt-welding and seamless technology, ensuring seamless integration within your systems. Connection types include butt welded, socket welded, and threaded options, providing flexibility based on project requirements.

Surface Treatments

Surface treatments enhance the durability and appearance of our elbows. For stainless steel, we offer polishing and sand-blasting. For carbon and alloy steel, options include black painting, varnish paint, anti-rust oil, and galvanization (both hot and cold). These treatments are vital for protecting against corrosion and prolonging the life of the product.

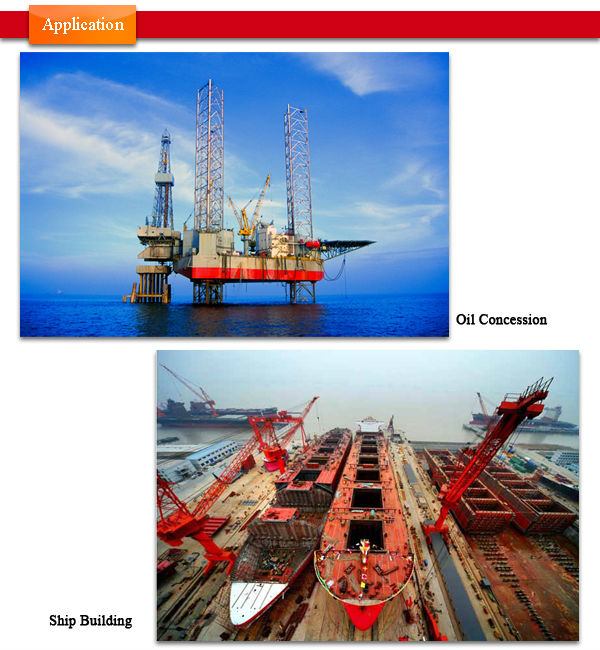

Applications

Our Stainless Steel Elbow is widely used in various applications, including:

Petroleum and Gas Industries

Chemical Processing Plants

Power Generation Facilities

Metallurgy and Shipbuilding

Construction Projects

These applications showcase the versatility and reliability of our products in critical industries.

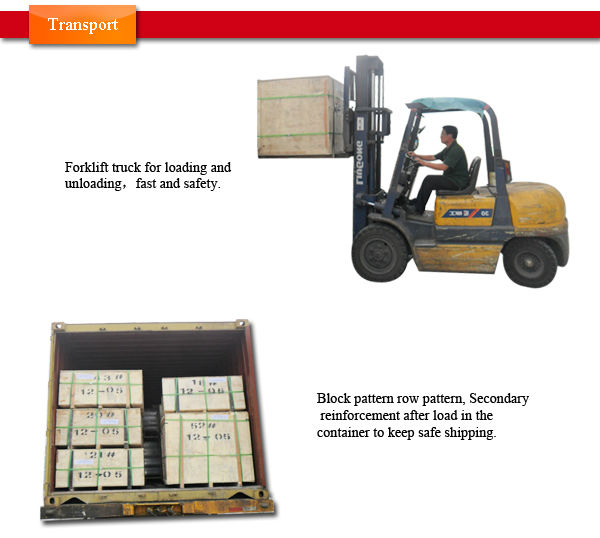

Packaging and Shipping

We prioritize the safe delivery of our products. Our elbows are packaged using plastic film, wooden cases, or pallets, tailored to customer requests. With a production capacity of 50,000 tons/year, we ensure prompt delivery within 7-30 days, depending on order quantity.

Quality Certifications

We are committed to maintaining the highest quality standards, as demonstrated by our certifications, including API, ISO9001:2000, CE, and BV. These certifications validate our dedication to quality and safety in manufacturing.

Advantages of Choosing Us

Competitive Pricing: We offer reasonable prices without compromising on quality.

Abundant Stock: With a rich inventory, we ensure prompt delivery.

Experienced Supply Chain: Our experience in supply and export translates into reliable service.

Dedicated Support: Our team is ready to provide assistance throughout the purchasing process.

Contact Us

For more information about our Stainless Steel Elbow and to explore how our products can meet your needs, please visit our products page or contact us directly. We look forward to assisting you in enhancing your projects with our high-quality piping solutions.

carbon steel sch40 pipe elbow 90deg dimensions

A.elbow,tee,reducer.

B.ISO9001:2008

C.ANSI,ASME,DIN,JIS,BS

D.carbon/ss steel

Product | DN200 Seamless Elbow A234 WPB |

Size range | 1/2"-24" are made by seamless pipes, above up to 72" are made by welded pipes |

Thickness | SCH20 SCH40 STD SCH60 SCHXS SCH80 SCH160 SCHXXS etc are available |

Angle&Radius | 45 degree,r=1.5d (long radius),r=d(short radius) |

Standards | ASTMA234,ASTM A420,ANSI B16.9/B16.28/B16.25,ASME B16.9,

JIS B2311-1997/2312, JIS B2311/B2312, DIN 2605-1/2617/2615,

GB 12459-99,EN Standard etc. |

Materials | Stainless steel(ASTM A403 WP304,304L,316,316L,321. 1Cr18Ni9Ti, 00Cr19Ni10,00Cr17Ni14Mo2, ect) Carbon steel(ASTM A234WPB,,A234WPC,A420WPL6. 20#,Q235,10#,20#,A3, Q235A, 20G,16Mn, ect) Alloy steel(ASTM A234 WP12,WP11,WP22,WP5,WP9,WP91,16MnR, Cr5Mo, 12Cr1MoV, 10CrMo910,15CrMo, 12Cr2Mo1, ect) |

Technology | Butt-welding,Seamless |

Connection | But welded, socket welded, threaded |

Surface | stainless steel: Polishing, Sand-blasting carbon steel/alloy steel: Black painting,varnish paint, anti rust oil, hot galvanized, cold galvanized, 3PE,etc |

Application | Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc |

Package | Plastic film, wooden cases ,wooden pallet, or according to customers' request |

Certificate | API, and ISO9001:2000 Certificates,CE,BV, etc. |

Capacity | 50000tons/year |

Advantages | 1.Reasonable price with excellent quality

2.Abundant stock and prompt delivery

3.Rich supply and export experience, sincere service

4. Reliable forwarder |

Port of loading | Xingang (Tianjin) port |

Payment Terms | 30% down payment, the balance 70% T/T before the shipment Or L/C at sight. |

Delivery Time | 7-30 days, according to the order quantity. |